分析化学

The purity of acid is substantially important in trace-element and ultra-trace element analysis. The higher the purity, the lower the background.

Commercial high-purity acid is not only super expensive, but the purity drops after coming in contact with air.

The acid purification process is the most economical method for high-purity acid production.

Our Acid Purifier, known as Acid Purification System or Acid Distillation System, uses the sub-boiling technique to ensure a high purity acid vapor is produced, which then condenses to the desired high-purity acid widely used in AAS, ICP-OES, ICP-MS, AFS and other spectroscopy analysis.

Technical advantage:

The specially treated temperature sensor has the same corrosion resistance as PTFE material. So, it can be directly immersed into the acid to measure the real temperature of the acid liquid instead of the heater. As a result, accurate temperature control ensures that the acid liquid maintains sub-boiling temperatures during the purification process.

All wetted parts are made of ultra pure PTFE or PFA, the best corrosion-resistive materials.

Too high a temperature causes the decrease of the purity dramatically. Too low a temperature causes the unbearable low production.

Thanks to RTC technique and the state-of-the art structure design, AP300 is able to control the temperature accurately and reasonably and get the best balance between efficiency and effect.

4、Excellent Performance

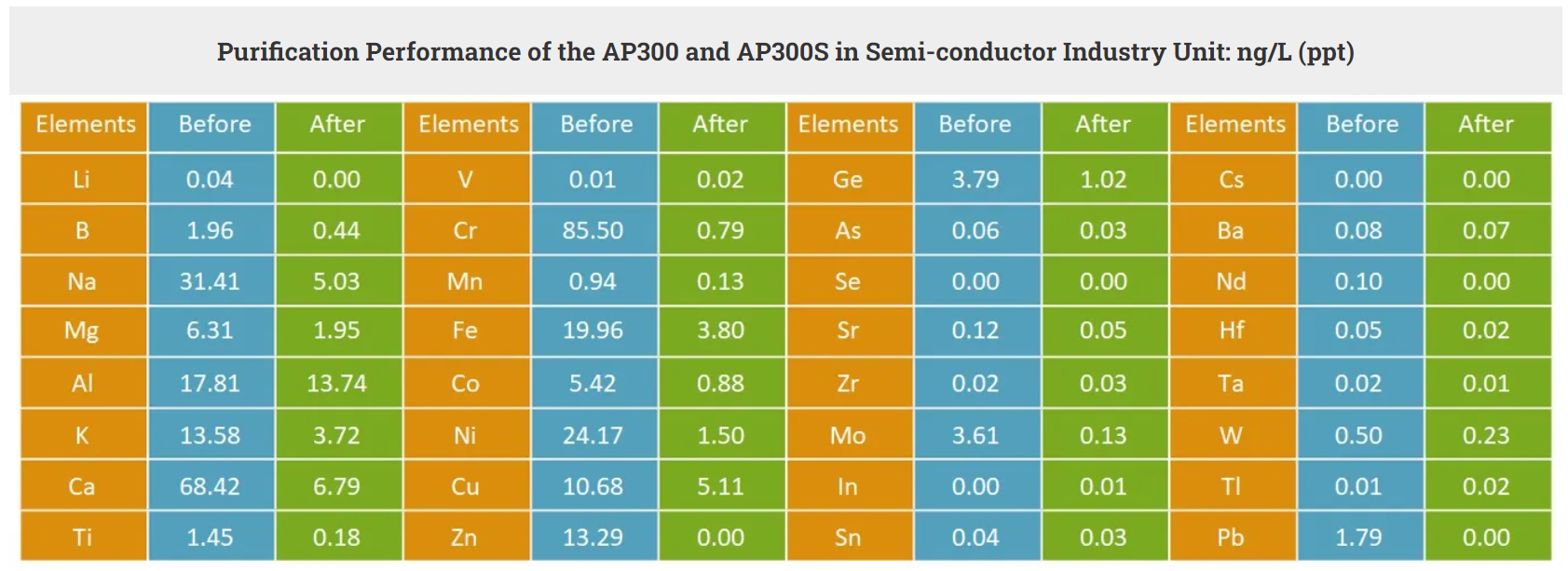

Can purify low-purity trace metal grade (1 ppb) to high-purity grade (10 ppt).

5、PTC Semi-conductor Heater

Under the unlikely event that all temperature control systems have failed, the maximum temperature is autonomously controlled by the heater and will not exceed 482 oF which prevents damage and risk of fire.

PTC heater might be the best kind for Acid Purification/Distillation System.

Traditionally, both the purification chamber and the purified acid bottle required an air vent to maintain air pressure balance, resulting in inevitable acid vapor leakage.

AP300 uses a unique high-performance acid vapor scrubber which eliminates this problem - yielding an absorbing efficiency which exceeds 99% and an adsorbing capacity of 50%.

Three non-contact liquid level sensors monitor the level of raw acid and purified acid in real time. Once the level of raw acid is too low, or the level of purified acid is too high, the system will be immediately stopped in order to avoid the dry running or the acid overflowing. The third sensor will stop the pump from adding too much acid into the purifier.

Despite the cost, the system incorporates two distinct flowpaths, each equipped with its own pump for filling and draining, respectively. This design completely prevents the contamination of the clean acid flowpath by the waste acid.

Automatic acid refill, removal and cleaning with the programmable pumps.